PARALLEL

AND COUNTER CURRENT FLOW IN A DOUBLE PIPE HEAT EXCHANGER

OBJECTIVES

➤ To determine the LMTD and overall heat transfer coefficient of the heat exchanger during parallel and counter current flow configuration.

➤ To estimate the effectiveness

of the heat exchanger under parallel and counter current flow conditions.

DATA SHEET

t11 COLD WATER INLET

t12 COLD WATER OUTLET

t21 HOT WATER INLET

t22 HOT WATER OUTLET

RESULTS & DISCUSSIONS

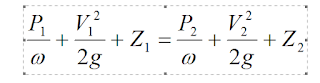

➤ Compute the LMTD (log mean temperature difference), rate of heat transferred by hot and cold water (Q) and overall heat transfer coefficients (U) for both parallel and counter current flow configurations.

➤ Compute

the effectiveness factor ’h’ for parallel and counter current flow

configurations.

➤ Plot

the temperature profiles for cold as well as hot water for parallel and

counter current flow configurations.

➤ Compare the amount of heat transferred in both the flow

configurations and provide reasons for the difference.